When it comes to shaping safe, functional, and attractive public spaces, bollards play an essential role. They guide traffic, protect pedestrians, and define boundaries — all while contributing to the overall look of an area. There is a wide range of choices on the market when it comes to sizes, shapes, additional features, and materials. Traditionally, bollards have been made from steel, iron, or concrete, but in recent years, polyurethane bollards have become a popular alternative, offering a combination of resilience, flexibility, and low maintenance that makes them the smart choice for many modern environments.

What Is Polyurethane?

Polyurethane (often abbreviated to PU) is essentially a type of plastic – a man-made polymer that can be formulated to have varied qualities, such as increased flexibility or rigidity, depending on its intended use. It is created by chemically reacting polyols (a type of alcohol with multiple hydroxyl groups) with isocyanates, in the presence of catalysts and additives. Adjusting these ingredients is what allows manufacturers to change the properties of the final product, which is what makes polyurethane so convenient and widespread – PU is used in anything from soft foam mattresses to rigid insulation boards and, of course, bollards.

As a material, polyurethane is known for its impact resistance, weather durability and design flexibility. For bollards, PU is useful as it allows manufacturers to make flexible bollards which, when struck, return to their original shape. This gives them an edge over traditional bollards in some use cases, making them especially effective in areas prone to vehicle contact — such as car parks, forecourts, and busy pedestrian zones. Polyurethane is also used in non-flexible models, such as our Borough Style Bollard, which is made from high-performance polyurethane cast onto a central steel core.

Key Benefits of Polyurethane Bollards

In the context of bollards, polyurethane is popular because it combines strength with flexibility. If a vehicle bumps into a bendy PU bollard, it will flex and return to position once the load is removed, protecting both the bollard and the vehicle — something concrete or steel bollards can’t do. Polyurethane bollards, flexible or not, are designed to withstand the demands of modern environments and provide reliable protection while keeping long-term costs low.

Durability in All Conditions

Polyurethane is resistant to corrosion, cracking, and weathering. Unlike a steel bollard, a polyurethane bollard won’t rust, and unlike concrete, it won’t chip or spall in freezing conditions. The durability of PU bollards makes them a preferred choice for specifying street furniture. In addition to being corrosion- and rust-resistant, they also withstand many chemicals—including saline and uric acid—and are highly resistant to chipping and abrasion. This gives polyurethane products a longer, maintenance-free lifespan and helps reduce ongoing costs, even in demanding environments.

Impact Resistance and Flexibility

Accidental vehicle contact is a common risk in car parks and urban spaces and is one of the primary reasons for installing bollards in the first place. The benefit of choosing polyurethane bollards is that some models can be flexible on impact and bounce back. This reduces the risk of costly vehicle damage and avoids the need for frequent bollard replacements. These bendy bollards can’t replace anti-ram ones where security might be paramount, but they are incredibly useful in accident-prone areas, such as car parks, where minor collisions may occur at slower speeds.

Low Maintenance

Polyurethane bollards are designed to withstand demanding environments with minimal upkeep. Because the material is non-porous, dirt, grime, and stains don’t easily penetrate the surface, meaning they can be cleaned quickly with just soap and water if needed. Unlike metal bollards, they will not rust, corrode, or require regular repainting, and unlike concrete, they won’t chip, crack, or spall over time. Their built-in UV resistance helps prevent fading or discolouration, even when exposed to constant sunlight. This long-lasting resilience translates into lower lifecycle costs and fewer maintenance demands—making polyurethane bollards a smart, cost-effective investment for both indoor and outdoor applications.

Design Versatility

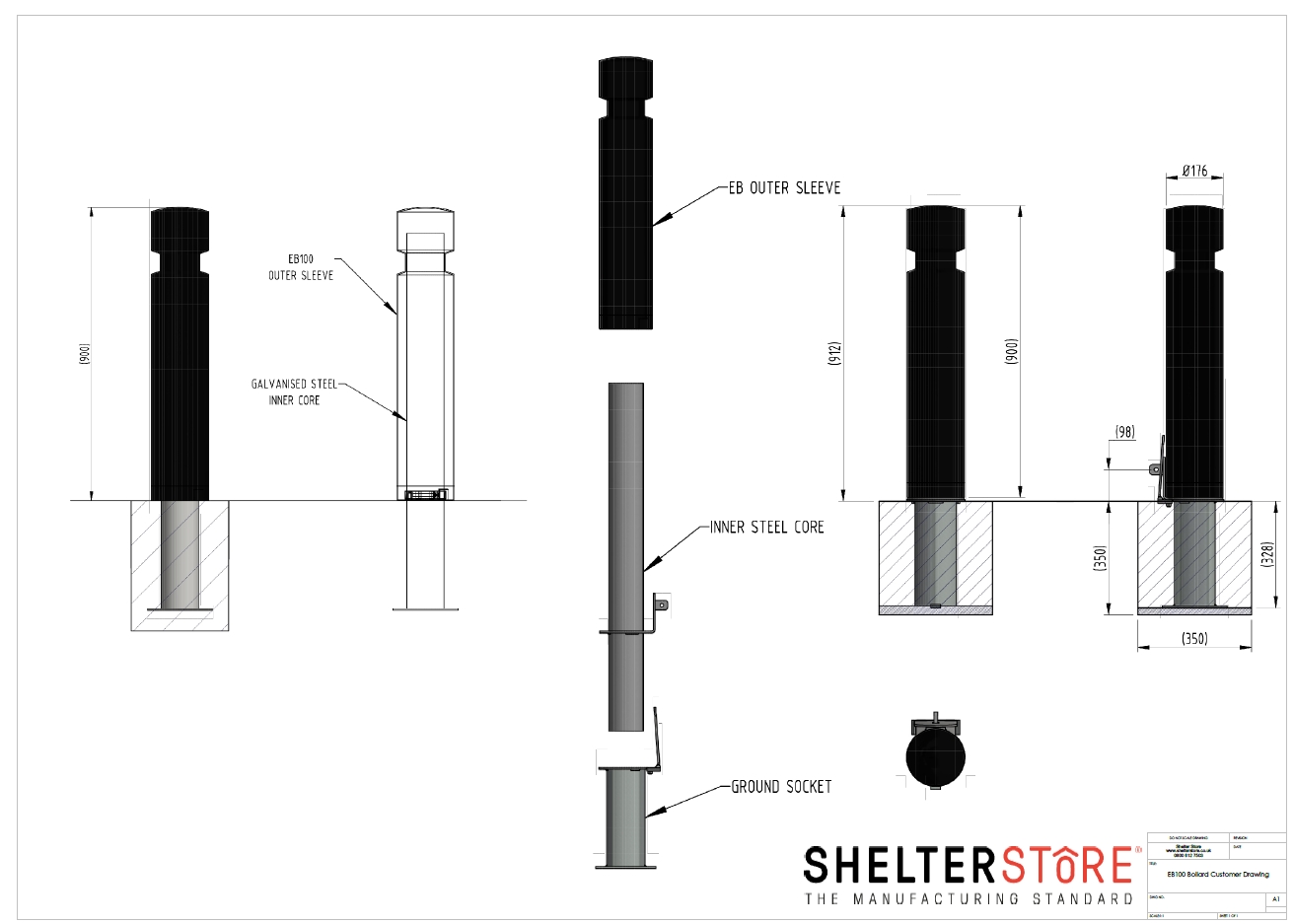

Polyurethane bollards can be manufactured in a wide range of shapes, finishes, and colours. This allows us to offer both sleek and contemporary designs, such as the MDPE-made EB100 Bollard, alongside more traditional styles with heritage appeal, like the Deval Style Bollard. PU bollards offer aesthetic flexibility without compromising performance. Reflective banding can also be added for increased visibility and safety.

Safer for Vehicles and Pedestrians

The bendable PU bollards help minimise injury risks and reduce vehicle repair costs by flexing under pressure rather than remaining rigid. This makes them particularly well-suited to environments where both safety and protection are paramount, such as schools, retail parks, and transport hubs.

For areas where a stronger physical deterrent is required, non-bendable PU bollards are also available. These rigid versions offer greater resistance to impact, helping to control vehicle movement and protect high-value infrastructure or pedestrian zones. Like their flexible counterparts, they are resistant to rust, corrosion, and chipping, ensuring long-term performance with minimal maintenance. By combining bendable and rigid PU bollards in the right settings, site managers can achieve an optimal balance of safety, durability, and protection.

Where to Use Polyurethane Bollards

Polyurethane bollards are ideal for:

- Retail car parks – to separate pedestrian walkways from vehicle lanes

- School entrances and campuses – providing safety barriers without creating a harsh, industrial look

- Transport hubs – managing flow while withstanding heavy use

- Business complexes – offering a sleek, modern appearance that complements contemporary architecture

- Heritage or conservation areas – where traditional-style bollards are required but durability is still key

A Modern Choice for Modern Spaces

Polyurethane bollards bring together the best of both worlds: the resilience and strength required to withstand everyday wear and tear, and the flexibility to minimise damage in low-speed impacts. Unlike traditional steel, iron, or concrete alternatives, PU bollards won’t rust, corrode, or crack, making them a truly low-maintenance solution with a long service life. Their versatility in design — from sleek modern finishes to heritage-style options — ensures they enhance the look of any setting while delivering dependable performance.

Whether you need flexible bollards to reduce vehicle damage, rigid bollards for higher levels of protection, or a combination of both, polyurethane offers a future-proof solution that strikes a balance between safety, durability, and aesthetics. For public spaces, car parks, schools, and transport hubs, PU bollards represent a practical choice and a cost-effective investment in creating safer, smarter, and more attractive environments.